"Do The Right Thing" - this steadfast motto lies at the heart of GLIDE, guiding our mission to transform the world of stand-up paddleboarding (SUP). Our journey began in 2008 when professional kayaker Ken Driscoll transformed a career-ending injury into an inspiring venture, joined by visionary entrepreneurs Scott Knorp and Ken Apperson. United by a shared dream, they set out to establish a global outdoor brand centered on performance, innovation, and responsible corporate citizenship.

At GLIDE, we're passionate about creating top-quality, performance-driven paddleboards. Our design philosophy is deeply rooted in understanding the natural forces of water and wind, enabling us to develop cutting-edge boards that harmoniously interact with the environments they traverse. Our dedication to excellence, education, and community engagement has built a legacy that resonates with paddleboarding enthusiasts worldwide.

Our unparalleled performance, commitment to paddleboarding knowledge and expertise, and unwavering customer support foster trust and loyalty among our customers. When you join the GLIDE community, you're not just purchasing a paddleboard – you're becoming part of a movement dedicated to the future of exceptional water sports. Our enthusiastic team, inventive designs, and commitment to responsible practices set us apart in the paddleboarding industry.

Inclusive and diverse, the GLIDE community is composed of customers, employees, partners, and brand ambassadors who share our love for the outdoors and the desire to make a positive impact. We actively engage with local and global communities, supporting initiatives that promote responsible recreation, environmental stewardship, and conservation efforts. Together, we're shaping the future of water sports, one paddleboard at a time.

GLIDE stands out not only for our innovative designs and exceptional performance but also for our dedication to giving back and fostering a culture of social responsibility. We actively seek partnerships with like-minded organizations, non-profits, and businesses that share our passion for responsible recreation and environmental stewardship.

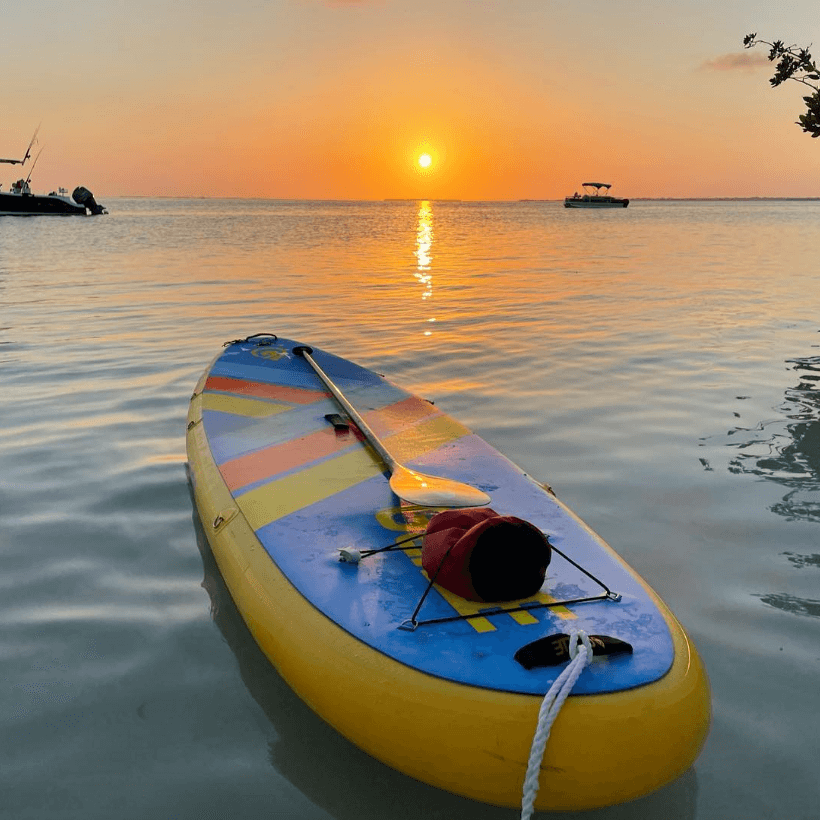

With a GLIDE paddleboard, the possibilities for adventure are boundless. From exploring tranquil lakes, tackling exhilarating rapids, or venturing into the open ocean, our boards empower paddlers to push their limits and savor the thrill of the sport. As we continue to grow and evolve, we invite you to embark on this journey with us, exploring the wonders of the world while enjoying the incredible experiences that paddleboarding has to offer. Together, we can create a brighter future for generations of paddleboarders to come.

At GLIDE, we push the boundaries of paddleboard design, driven by our deep understanding of natural forces and unwavering commitment to sustainability. Our award-winning design team creates performance-driven paddleboards by incorporating cutting-edge technologies like welded seam technology, 1300D military-grade PVC construction, woven drop-stitch core, and the revolutionary Glide Surface Shield (GSS) technology, all at our state-of-the-art 11,000 square foot R&D facility in Salt Lake City!

Our welded seam technology uses heat, pressure, and electromagnetic energy to create a molecular bond between materials, resulting in stronger, more durable, and airtight seals. This enhances stability, maneuverability, and overall performance, while also providing a lighter-weight board that's easy to transport.

The 1300D military-grade PVC construction ensures exceptional durability and stiffness, while the woven drop-stitch core allows the board to maintain its shape and rigidity, delivering a smooth ride across various water conditions!

Our game-changing Glide Surface Shield (GSS) technology, developed specifically for whitewater conditions, offers unparalleled durability, enabling our boards to withstand even the most extreme conditions without compromising performance.

These advanced technologies not only deliver superior performance but also align with our mission to protect the environment and promote sustainable living by eliminating the need for glue and solvents in the manufacturing process. This makes our boards more environmentally friendly and less harmful to both the environment and those involved in the manufacturing process.

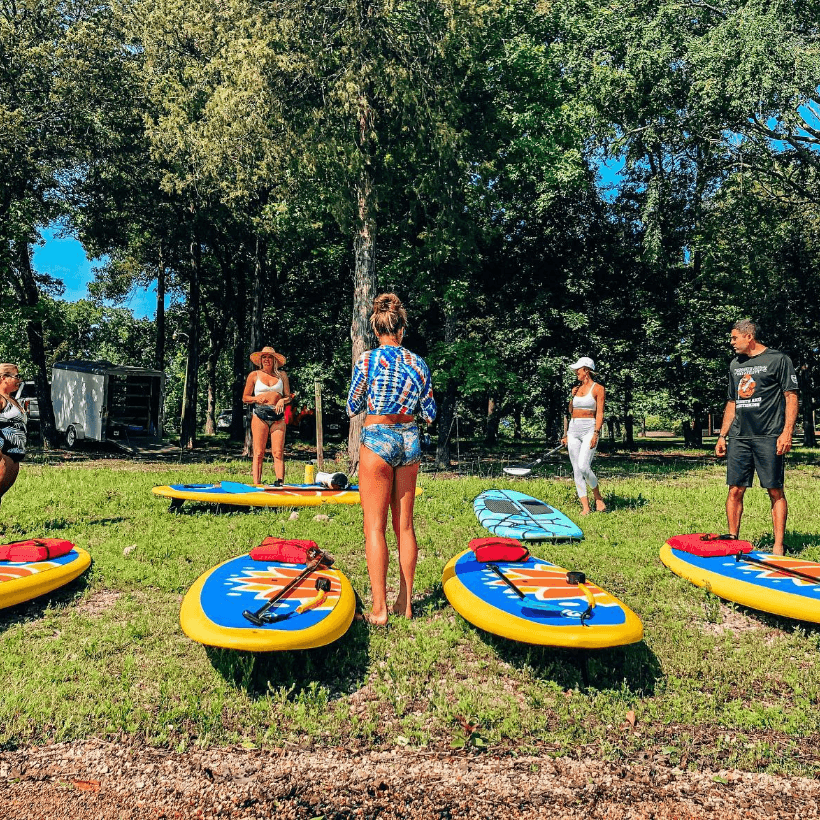

At GLIDE, we cater to paddlers of all skill levels, from first-time paddlers to professional whitewater enthusiasts. Our diverse range of boards is designed to meet the needs of various water sport activities, including SUP yoga, fishing, and whitewater paddling. We promise to have the perfect board to elevate your paddleboarding experience!

Our design journey is continuous as we strive to improve our boards and reduce our environmental footprint. GLIDE remains committed to pushing the boundaries of paddleboard design and technology, staying at the forefront of the industry while contributing to a more sustainable world. Experience the perfect fusion of innovation, performance, and sustainability that defines the essence of GLIDE paddleboards!

At the heart of GLIDE lies a vibrant culture that unites adventure-seekers, environmental stewards, and paddleboarding enthusiasts from all walks of life. Our values of innovation, performance, and sustainability are deeply ingrained in our DNA, shaping the way we approach our work, our relationships, and our commitment to preserving the planet's precious water resources.

Adventure is at the core of our culture, as we celebrate the spirit of exploration that brings our global family of paddlers together. We believe that every stroke on the water opens up new horizons, pushing our limits and fueling our passion for the sport. This shared sense of adventure fosters camaraderie within the GLIDE community, inspiring us to create lasting memories while discovering the wonders of the world.

Community is the backbone of our culture, as we cherish the connections we've built with customers, employees, partners, and brand ambassadors who share our love for the outdoors and our dedication to protecting the environment. Through events, collaborations, and our ambassador program, we engage with our community, encouraging the growth and development of paddleboarding and promoting a more sustainable approach to water sports.

Sustainability is at the heart of our culture, guiding our decisions and actions as we strive to minimize our impact on the environment. From our eco-friendly product designs to our responsible manufacturing practices and community initiatives, we are committed to fostering a culture of social and environmental responsibility. This unwavering dedication to sustainability resonates with our customers, empowering them to make more conscientious choices and join us in our mission to protect the planet.

Education and continuous improvement are integral aspects of our culture. We believe that by sharing our knowledge, expertise, and passion for paddleboarding, we can create a more informed and responsible community of paddlers. Through our workshops, training sessions, and online resources, we empower our community to develop their skills, expand their understanding of the sport, and embrace a more eco-conscious lifestyle.

The culture at GLIDE is truly unique, bringing together people from diverse backgrounds, united by their love for paddleboarding, adventure, and the environment. By joining the GLIDE community, you become part of a movement that values innovation, performance, sustainability, and camaraderie. Together, we can make a meaningful impact on the world of water sports and contribute to a brighter, more sustainable future for generations to come.

The roots of GLIDE's extraordinary journey can be traced back to a life-changing event that transformed the path of our founder, Ken Driscoll. As a professional kayaker with a passion for water sports and a keen understanding of the complex dynamics of water and wind flow, Ken's world was forever altered when he decided to paddle over a 50-foot waterfall! The resulting back injury marked the end of his kayaking career and set the stage for a new chapter in his life.

Undaunted by adversity, Ken turned his attention to stand-up paddleboarding (SUP) and began a relentless pursuit of innovation. He recognized the potential for a paddleboard specifically designed for the extreme conditions of whitewater rapids, and with unwavering determination, he developed our revolutionary Glide Surface Shield (GSS) technology! This breakthrough marked the birth of GLIDE and laid the foundation for our commitment to creating high-quality paddleboards that push the boundaries of performance and design.

Ken's inspiring journey caught the attention of entrepreneurs Scott Knorp and Ken Apperson, who shared his passion for water sports and his vision for an innovative outdoor brand. Together, the trio embarked on a mission to build a global company focused on performance, innovation, and responsible corporate citizenship. From a small garage to the thriving, worldwide presence we enjoy today, GLIDE has remained true to its roots, driven by a shared sense of purpose and a commitment to doing the right thing.

Our backstory is a testament to the power of resilience, determination, and innovation in the face of adversity! It serves as a constant reminder of our humble beginnings and the extraordinary journey that has shaped our values and culture. At GLIDE, we believe that every challenge presents an opportunity to learn, grow, and create something remarkable. This unwavering spirit of perseverance continues to fuel our passion for pushing the limits of paddleboard design and technology, inspiring us to create a brighter future for our global family of paddlers.

In a crowded market of paddleboard manufacturers, GLIDE stands out as the clear choice for discerning paddleboarding enthusiasts who value performance, innovation, and exceptional quality! Our commitment to crafting exceptional boards with cutting-edge technology sets us apart from our competitors, giving you an unparalleled paddling experience. Here's why choosing GLIDE means choosing the best in the industry:

Choose GLIDE and experience the incredible blend of innovation, performance, and design that defines the essence of our paddleboards. Join us on this exciting journey as we continue to revolutionize the world of stand-up paddleboarding, creating unforgettable experiences for paddlers around the world.

The world of stand-up paddleboarding awaits you, and there's no better way to dive in than with GLIDE by your side. Our exceptional boards and vibrant global community make us the perfect partner for your paddleboarding adventures. Don't miss out on the opportunity to become part of something bigger than yourself - join our movement and embrace the GLIDE way of life today!

The journey ahead is full of endless possibilities and breathtaking experiences. With GLIDE's innovative paddleboards and supportive community, you'll have everything you need to make the most of your time on the water. So gear up, dive in, and let GLIDE propel you towards a lifetime of incredible paddleboarding adventures!