What Makes a Cross Woven Drop Stitch Paddle Board Better Than the Rest?

Cross-woven drop stitch is the pinnacle of inflatable paddle board design. Its multi-directional fiber matrix provides unmatched stiffness, strength, and lightness, giving riders the hard-board feel they crave with the convenience of an inflatable.

Combined with Glide’s AeroMatrix™ and ThermoFuse™ technologies, it represents the future of SUP performance.

Table of contents

Woven vs. Cross-Woven: The Next Evolution Why It Matters Cross-Woven vs. Standard Inflatable Paddle Boards Glide’s AeroMatrix™ and ThermoFuse™ Construction Real-World Advantages for Paddlers Cross-Woven Drop Stitch vs. Other Technologies Maintenance Tips for Longevity Final Thoughts

Woven vs. Cross-Woven: The Next Evolution Why It Matters Cross-Woven vs. Standard Inflatable Paddle Boards Glide’s AeroMatrix™ and ThermoFuse™ Construction Real-World Advantages for Paddlers Cross-Woven Drop Stitch vs. Other Technologies Maintenance Tips for Longevity Final Thoughts

If you’ve ever wondered how inflatable paddle boards can feel as solid as hard boards, the answer lies deep inside the core. The secret? Cross woven drop stitch paddle board technology is the most advanced material innovation in inflatable SUP design.

Inside every Glide board, this next-generation core interlocks thousands of high-tensile threads in a crisscrossed pattern. The result is a board that’s lighter, stronger, and more rigid, performing like a hard board while still packing down small enough to travel anywhere.

The Science Behind Drop Stitch Technology

Traditional inflatables use vertical threads to connect the top and bottom layers of the board. When inflated, these threads create tension that gives the board its flat, firm surface—preventing it from bulging like a pool float. This is called drop stitch construction.

While standard drop stitch has been around for years, it has limitations. Under heavy pressure, these vertical fibers can stretch slightly, causing flex in the middle of the board. Over time, this results in a “spongy” feeling and reduced efficiency on the water.

Enter woven and cross-woven drop stitch—technological upgrades that dramatically improve performance, stiffness, and longevity.

Woven vs. Cross-Woven: The Next Evolution

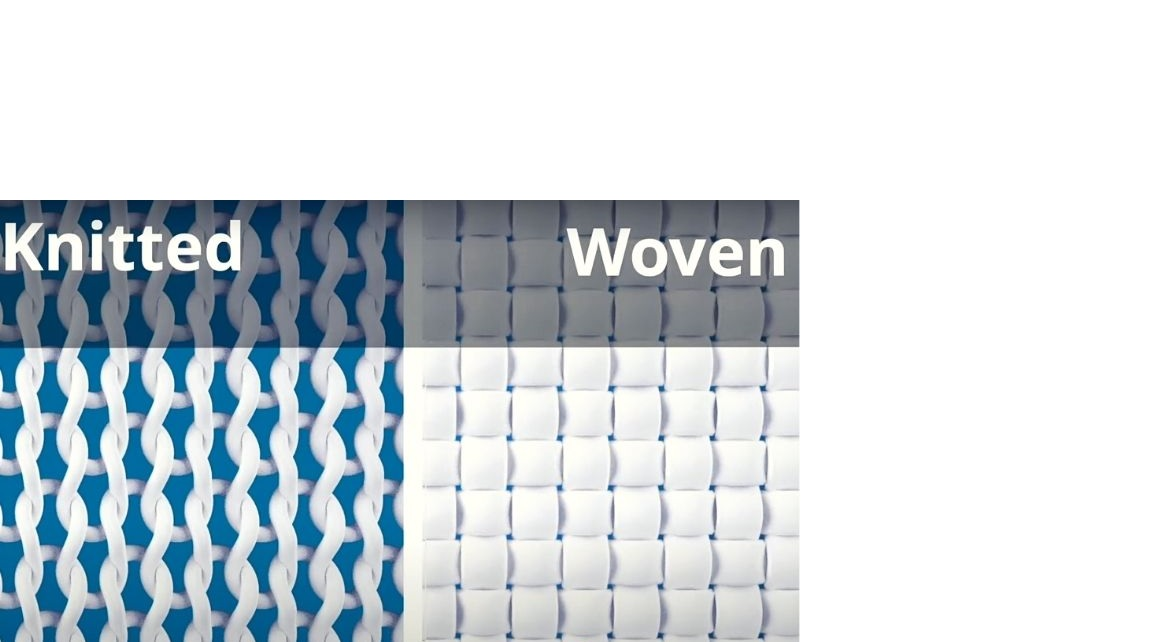

The difference between woven and cross-woven construction comes down to the direction of the fibers.

-

Woven drop stitch uses horizontal and vertical threads woven tightly together to create a stronger bond than the older knitted style.

-

Cross-woven drop stitch takes it further. It weaves fibers diagonally across multiple angles, creating a “cross brace” effect that evenly distributes tension and eliminates flex underfoot.

This unique pattern boosts rigidity by up to 25% while reducing overall weight by nearly 30%—a massive leap in paddle board engineering.

Why It Matters

-

Stiffer feel: Less flex means smoother, faster paddling.

-

Lighter weight: Easier to carry, inflate, and transport.

-

Enhanced glide: Every paddle stroke transfers energy more efficiently.

-

Longer life span: Stronger fibers resist stretching and deformation over time.

Cross-Woven vs. Standard Inflatable Paddle Boards

When you compare an average inflatable SUP to a cross-woven model like Glide’s AeroMatrix™, the difference is immediate.

Standard boards often use knitted drop stitch, a less dense weave that sacrifices stiffness for cost savings. These looser fibers stretch under pressure, making the board feel soft or unstable.

By contrast, cross-woven boards use multi-directional tensioning, locking in the board’s structure even under high PSI. The result:

-

Higher PSI tolerance—inflate up to 25 PSI without losing integrity.

-

Superior tracking—less wobble, straighter lines.

-

Greater stability—ideal for beginners, yoga, or fishing.

-

Longer durability—fewer issues with seam fatigue or stretching.

You’ll feel the difference from the very first paddle.

Glide’s AeroMatrix™ and ThermoFuse™ Construction

Glide’s AeroMatrix™ Cross-Woven Drop Stitch sets a new benchmark in inflatable board technology. Each Glide Elite model pairs this advanced core with ThermoFuse™ triple-layer fused rails—a process that heat-bonds PVC layers instead of using glue.

This fusion method eliminates weak points, reduces weight, and strengthens the seams, resulting in:

-

Seamless rigidity from nose to tail.

-

Military-grade durability and puncture resistance.

-

Eco-friendly manufacturing with zero adhesive waste.

-

A board that feels solid underfoot but still rolls up for travel.

Together, these technologies deliver a ride that outperforms nearly every other inflatable SUP on the market.

Real-World Advantages for Paddlers

Every construction upgrade translates directly into on-water performance. Whether you’re a beginner or a seasoned paddler, a cross-woven board offers noticeable benefits:

-

Beginners: Enjoy a more stable, confidence-building platform that resists tipping.

-

Travelers: Lighter weight means easier transport and faster inflation.

-

SUP Yogis: A rigid, non-flexing deck creates the perfect balance for poses.

-

Anglers: A solid base for casting, reeling, and standing without wobble.

-

Tourers: Superior tracking and speed for long-distance efficiency.

A cross-woven board simply feels different—smoother, more responsive, and more connected to the water.

Cross-Woven Drop Stitch vs. Other Technologies

While many brands use terms like “dual-layer” or “reinforced PVC,” these are only part of the story. What truly separates Glide’s boards is the combination of materials and construction methods:

Technology

Description

Performance Impact

| Knitted Drop Stitch | Basic vertical fibers; low density | More flex, less control |

| Woven Drop Stitch | Horizontal + vertical threads | Better stiffness, moderate weight |

| Cross-Woven Drop Stitch (Glide AeroMatrix™) | Multi-angled fibers in crisscross weave | Maximum stiffness, lightest weight |

| ThermoFuse™ Rails | Heat-bonded triple PVC layers | Seamless durability, eco-friendly build |

This hybrid approach ensures each Glide board feels like a premium hard SUP but retains the packability of an inflatable.

Maintenance Tips for Longevity

Your board’s construction is built to last, but a few simple care tips can help you preserve that “like-new” feel:

-

Store it out of direct sunlight to prevent UV degradation.

-

Rinse with freshwater after paddling in saltwater.

-

Avoid over-inflating beyond recommended PSI.

-

Dry completely before storage to prevent mildew.

-

Use a board bag for extra protection during transport.

With proper care, a cross-woven SUP can easily last 8–10 years or more—outlasting most traditional inflatables.

Final Thoughts

The cross-woven drop stitch core is more than a technical buzzword—it’s the backbone of modern inflatable paddle board performance. By weaving fibers diagonally, horizontally, and vertically, Glide’s AeroMatrix™ construction delivers unmatched rigidity, lightness, and durability.

Combined with ThermoFuse™ triple-layer rails, these boards set a new industry standard for stiffness and quality, giving paddlers a hard-board experience without sacrificing portability.

If you’re ready to upgrade, choose a board with cross-woven technology—you’ll feel the difference in every paddle stroke.

FAQs

What makes cross-woven drop stitch better than standard woven?

The diagonal weave distributes pressure evenly across the board, creating a stronger, lighter, and more rigid structure than traditional woven or knitted cores.

Can cross-woven boards handle higher PSI?

Yes. Glide’s AeroMatrix™ boards can safely reach 20–25 PSI, maintaining rock-solid rigidity and outstanding performance.

Which Glide boards use cross-woven technology?

It’s featured in the 2025 Elite lineup— Retro Elite, Lotus Elite, and Mako—each designed for maximum stiffness, speed, and stability.

Does it really feel like a hard board?

Absolutely. Most paddlers notice the difference instantly—stiffer underfoot, smoother glide, and less flex even under load.

How long will a cross-woven SUP last?

With regular care, expect 8–10 years of dependable use—far exceeding the lifespan of cheaper glued or knitted boards.